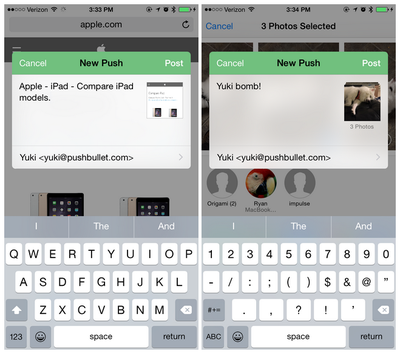

Following the release of Pushbullet for iOS, Mac, and Safari, we have been testing out the new software to see how well it keeps notifications, links, photos and other files in sync between devices. Pushbullet is the marriage of AirDrop, Notifyr and other OS X Yosemite features in one package, but is it a worthwhile alternative? Find out our first impressions in our hands-on video ahead.

The process of setting up Pushbullet takes just a few minutes. Depending on which platforms or web browsers you want to send and receive links and files between, download the Pushbullet apps or extensions that you need and make sure that iOS to Mac notifications and universal copy and paste are enabled in each app's preferences. iOS and Mac apps are available alongside Safari, Chrome, Firefox and Opera extensions.

You can optimize your experience further by going into the Mac app's preferences and checking off specific apps that you would like to receive iOS notifications from. For instance, if you already receive mail notifications on your desktop, then you probably don't need Pushbullet pushing the same mail notifications from your iPhone. Notification settings can be configured for both stock and third-party apps.

➜ Click here to read rest of article...

Facebook today updated its Paper app to version 1.2.5, adding several improvements to the app's photo management capabilities. It's now possible for users to access their "Favorited" photos album on iOS for faster sharing of preferred photos, and the Camera Roll in the app organizes photos by date.

Facebook today updated its Paper app to version 1.2.5, adding several improvements to the app's photo management capabilities. It's now possible for users to access their "Favorited" photos album on iOS for faster sharing of preferred photos, and the Camera Roll in the app organizes photos by date. In recent months, the Federal Trade Commission has taken a significant interest in carrier throttling practices and today handed down a ruling that could have future ramifications for carriers who throttle their unlimited customers.

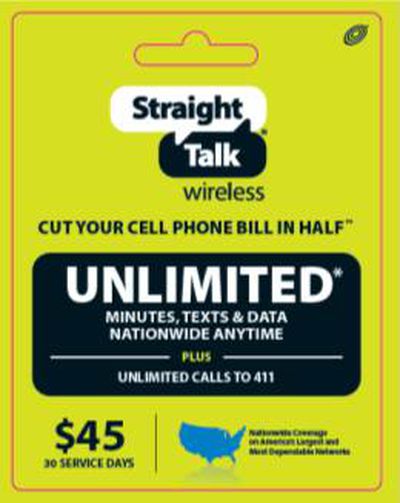

In recent months, the Federal Trade Commission has taken a significant interest in carrier throttling practices and today handed down a ruling that could have future ramifications for carriers who throttle their unlimited customers.

Yahoo chief executive Marissa Mayer, during the company's

Yahoo chief executive Marissa Mayer, during the company's  YouTube yesterday

YouTube yesterday

We've been extensively testing the Reach79 case on an iPhone 6 Plus for more than a week in various areas around the San Francisco Bay Area, but after several days of use, it remains difficult to conclusively say that the case improves signal in a meaningful way due to mixed test results. For a quick summary of what we found, scroll down to the "Bottom Line" section, or read on for our full results.

We've been extensively testing the Reach79 case on an iPhone 6 Plus for more than a week in various areas around the San Francisco Bay Area, but after several days of use, it remains difficult to conclusively say that the case improves signal in a meaningful way due to mixed test results. For a quick summary of what we found, scroll down to the "Bottom Line" section, or read on for our full results.