Back in 2010, Apple signed an exclusive agreement with Caltech spinoff Liquidmetal Technologies, providing Apple with the rights to use Liquidmetal's advanced metal alloys for consumer electronics purposes. Liquidmetal's amorphous metal alloys or bulk metallic glasses posses a number of characteristic properties such as high strength and corrosion resistance while remaining relatively light and able to be cast into a variety of forms.

Apple quietly tested Liquidmetal's alloys in the SIM card eject tool for the iPhone 3G, but the materials have otherwise not been confirmed to have appeared in any other Apple products, as one of alloys' inventors noted in 2012 that their use as major design materials was still several years in the future.

Evidence of Apple's continued interest with Liquidmetal alloys has surfaced a number of times over the past several years, including in a granted patent from July covering a process for mass producing thin sheets of the Liquidmetal alloys and a series of technical patent applications published in November describing methods of working with the alloys to create products.

A number of patent applications addressing additional innovations with Liquidmetal alloys have been published since that time, including a batch of 17 applications published just this past Thursday. Many of these applications are not yet listed as being assigned to Apple, but the inventors listed on the patents are Apple employees who have routinely been associated with the company's work on Liquidmetal alloys in the past.

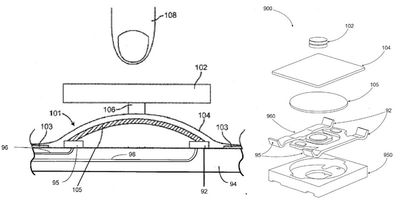

One of these patent applications proposes using Liquidmetal alloys in pressure sensors such as those found in buttons and switches on mobile devices, offering greater durability under repeated use. Figures accompanying the patent application closely resemble the iconic home button found on Apple's iOS devices.

Because switches on consumer electronic devices are operated frequently, the materials used to fabricate the switch must be capable of repeated deformation and return to their original configuration. The ability of a material to deform reversibly under stress is known as the material's elasticity. Above a certain stress, known as the elastic limit of a material or the yield strength, the metal material may deform irreversibly, becoming inelastic, exhibiting plasticity and adversely affecting the function and utility of the switch. [...]

A proposed solution according to embodiments herein for pressure sensors is to use bulk-solidifying amorphous alloys as the deformable material, and to measure the pressure based on the physical changes of the bulk-solidifying amorphous alloy as it is deformed.

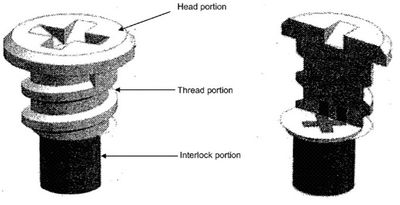

Another application published in mid-December describes how Liquidmetal alloys could be used as material for tamper-resistant screws to help secure devices against unauthorized access.

A proposed solution according to embodiments herein for tamper resistance is a fastener having a head portion and a tamper resistant bulk-solidifying amorphous alloy interlock portion, wherein the fastener and the substrate into which the fastener is fitted into are permanently fastened via an interlock formed from the interlock portion during the fastening process.

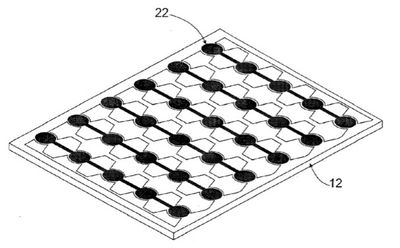

A third patent application addresses the use of Liquidmetal alloys as a substrate for touch sensors found in displays such as in Apple's iOS devices. Apple describes how discrete areas of crystallinity can be created on the amorphous metal substrate, allowing for greater control and higher density of touch sensing arrays, thus giving greater positional precision for touch sensing.

Most of the remaining patents are more technical in nature, addressing methods for working with Liquidmetal alloys or assessing their characteristics. One such patent application does, however, address methods for applying or transforming coatings to an amorphous material, allowing for increased durability and strength by protecting the underlying metal.

All of these patent applications were filed in June or July of 2012, suggesting that Apple may have made significant progress on these disclosed inventions since that time. It is unclear, however, whether any of the techniques or proposed components have made their way into shipping products or if they remain in the research or prototyping phase.

(Thanks, David!)